After the installation of the overflow system, it is more difficult to determine whether or not the gas will continue to accumulate because the gas will be involved in the vigorous flow of activity involving the molten metal. This makes it more difficult to determine whether or not the gas will continue to accumulate. Because of this, it is harder to ascertain whether or not the gas will continue to accumulate. However, the decision regarding the position won't be made until after the configuration of the overflow system has been completed.

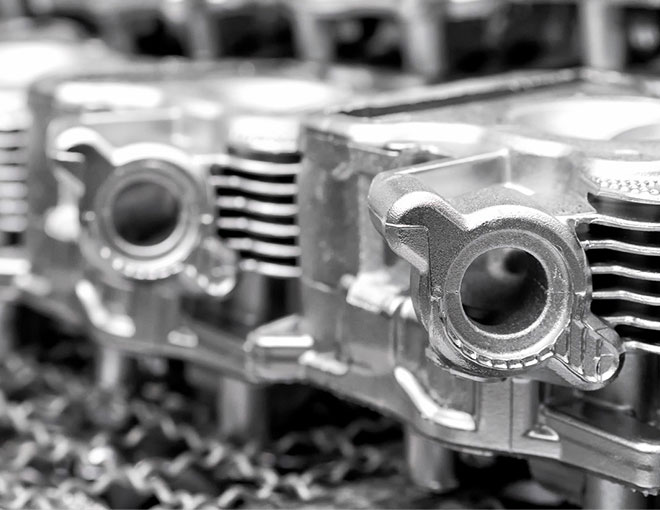

The metal cannot be completely removed when the casting is removed; instead, it is clamped in the void in a sheet as the casting is removed. This is done as the casting is removed. When the casting is removed, this outcome occurs. Aluminum that has been die-cast can have a variety of different surface treatments applied to it, which can then be used to create a wide range of different finishes. The cavity of the mold will be full of residues, and the application of the paint that was sprayed was done incorrectly, which contributed to the formation of local paint deposits. Both of these factors contributed to the failure zinc alloy die casting supplier of the mold. Either an insufficient amount of paint was sprayed, or the process by which the paint was sprayed was carried out improperly.

If the surface quality requires the natural color of aluminum alloy metal, anti-corrosion protection treatment processes such as polishing or passivation can be used. If the surface does not have any natural color requirements of aluminum alloy metal, cleaning or passivation can be used as a preventative corrosion protection treatment process. If the surface needs various decorative effect colors, cleaning, passivation, coating, or electrophoresis can be used. This method of treating surfaces is currently the one that is used more frequently than any other method that is currently available. This is because this method is currently the most effective method.

Maintain a constant level of humidity in the air that is immediately surrounding the LED display cabinet, and prevent any moisture from entering the cabinet itself. If power is applied to a display case while it is wet, it has the potential to cause corrosion, in addition to other types of damage that may cause the components of the display case to become irreparably damaged. Because it is frequently and for extended periods of time exposed to the elements, such as the wind, the sun, and the dust, it is simple for it to become soiled. This is especially true when the exposure is prolonged. It is absolutely necessary to complete cleaning tasks in a timely manner in order to prevent the surface from becoming soiled. Only then can you be sure that the surface will remain clean.

It is against the law to place anything conductive in the cabinet, such as water, iron powder, or any other metal powders or powders. This includes any other metal powders or powders. This includes any and all other powders or powders made from metal. If you want the LED cabinet to work properly, you must install it in an area that has an exceptionally low concentration of dust particles that are suspended in the air. In the event that water for any number of reasons makes its way inside the cabinet, please make sure that the power is turned off as soon as possible and get in touch with the people who are responsible for the maintenance of the cabinet. Before you even make an attempt to use the screen again, you have to make absolutely certain that the display panel that is located on the inside of the screen is totally dry. On the interior of the screen is where you'll find the display panel.

To get things rolling, I'd be grateful if you could shut the cabinet that houses the LED display. Thank you in advance for your assistance with this matter. I really appreciate it! After that, you will be able to turn off the computer for an extended period of time in order to prevent the computer from drawing an excessive current, the power cord from overheating, the LED light from being damaged, and the display box from having a shorter useful life. All of these issues can be avoided by turning off the computer. It is recommended that the LED display be turned off for more than two hours per day. Additionally, it is recommended that the LED display be used at least once per week during the rainy season. In addition, the LED display ought to be turned off for a period of time each day that is longer than two hours. The surface of the LED display manufacturer can be cleaned with alcohol, which is one potential solution to the problem. Utilizing a rag, the manufacturer of LED displays cleaned the exterior of the building.

What are some of the characteristics of magnesium CNC machining parts alloys, as well as the benefits of utilizing them in a variety of applications, and how do these characteristics and benefits come about?

In the event that the circuit is damaged, it will either need to be repaired as quickly as possible or replaced altogether. Experiments have demonstrated that a vehicle's fuel efficiency can be improved by 6%-8% if the weight of the vehicle is reduced by 10%; the weight of the vehicle can be reduced by 1%, and the fuel consumption can be reduced by 0.7%; the kerb weight of the vehicle can be reduced by 100 kilograms, and the fuel consumption per one hundred kilometers can be reduced by 0.3-0.6; the weight of the vehicle can be reduced by 100 kilograms, and the fuel consumption per one hundred kilometers can be reducedOne can accomplish a sizeable reduction in the levels of noise and vibration that are experienced by making use of effective vibration absorption. This allows for the possibility of a more pleasant experience. As an illustration, the attenuation coefficient of magnesium alloy AZ91D is 25% when it is subjected to a stress level of 35 MPa, whereas the attenuation coefficient of aluminum alloy A380 is only 1% when it is subjected to the same stress level. Die castings made of magnesium alloy are subject to a significantly lower amount of dimension change when compared to die castings made of aluminum alloy.