As a direct consequence of this, the stereo-curing 3D printer has established itself as the product of choice for a sizeable percentage of the user base. Which factors, as a result, have an impact on the level of accuracy steel CNC machining of the model that is produced by a 3D printer that uses light curing?.

1. The accuracy of the printing equipment, in and of itself

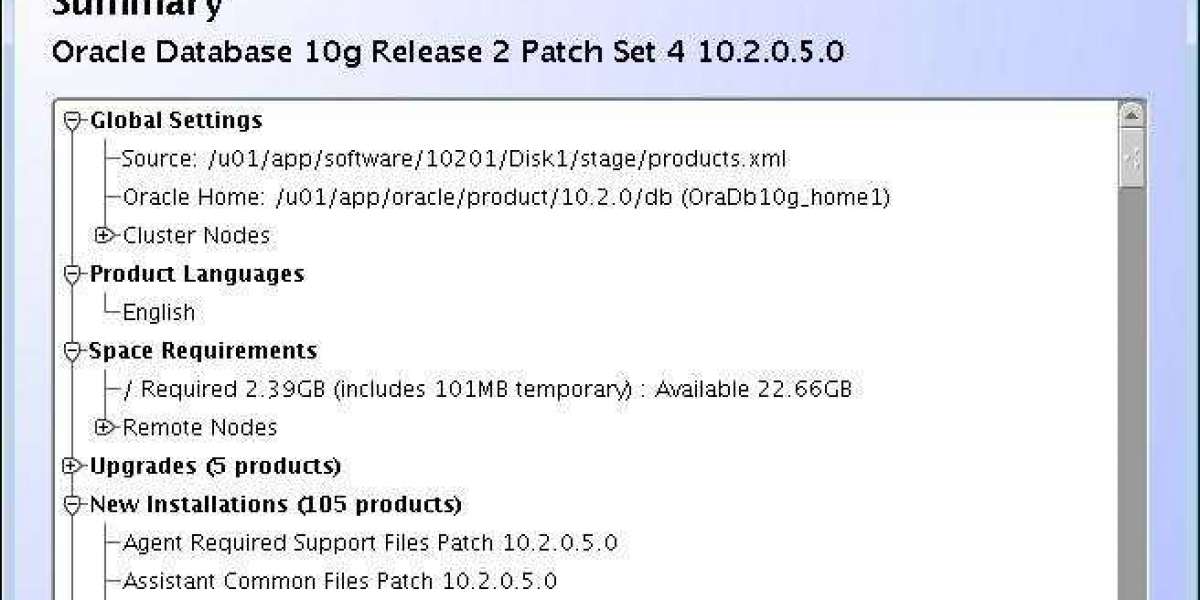

When thinking about 3D printing with light-curing, the first thing that needs to be understood is the resolution of the machine.The precision of the screen image, which describes the maximum number of pixels that the display is capable of displaying, as well as the resolution, is the primary factor that can cause the results to be inaccurate.This has a significant impact on the layer pattern as a result of the fact that the z-axis controls the printing up and down.If you are looking into purchasing a new piece of machinery, you can determine the level of accuracy it possesses by examining the quality of these two components.

2.The process of exporting the model in a format that can be recognized by the machine as well as the display of each layer of graphics while the process of printing is being carried out is referred to as "slicing," and the term is used to describe both of these processes.As a direct consequence of this, each layer now has a thickness, and the parameter setting gives the user the ability to modify the thickness of each layer on an individual basis.In a few of the curved sections, you can make out step patterns that are very distinct from one another.After the printing process is complete, there is a possibility that there will be differences between the model and the actual size of the object, in addition to a grainy appearance on the surface.In the event that the model sustains damage, the photosensitive resin that was used to construct it can be directly applied to the area that was harmed, and it can be hardened by exposing it to ultraviolet light. In this way, the damage can be concealed from view.The typical characteristics of the photosensitive resin

The quality of the photosensitive resin can have an effect on the adhesion properties of the material, as well as the stacking properties, and the flow of the liquid resin. In addition, the quality of the resin can have an effect on the liquid resin.If a resin machine of poor quality is used to move up and down horizontally, the surface quality will be poor, and the side surface quality will not be smooth due to the interference of the inclination angle, which will result in step lines. Additionally, the surface quality of the side will not be smooth due to the interference of the inclination angle.In addition, the quality of the surface will suffer if the machine is used to move vertically rather than horizontally.It is necessary to improve the quality of the photosensitive resin as well as the printing accuracy of the machine by adjusting the settings. It is essential to improve the printing accuracy of the machine by adjusting the settings.

Microbes are given a helping hand in the process of converting sunlight into electricity by nano-skyscrapers that have been printed using 3D printing technology. These grids provide an environment that is conducive to the rapid multiplication of bacteria that flourish in the presence of sunlight. After the bacteria had finished the process of photosynthesis, the researchers were able to extract the spent electrons that were left behind by the bacteria.

Other research organizations have been successful in extracting energy from photosynthetic bacteria. However, researchers from the University of Cambridge have discovered that by providing these bacteria with an appropriate environment, they can increase the amount of energy they extract by more than an order of magnitude. Other research organizations have been successful in extracting energy from photosynthetic bacteria. In addition, the findings shed light on previously unexplored avenues for the production of bioenergy. However, these technologies also have some drawbacks, such as their reliance on mining, the challenges that are associated with recycling, and the constraints that are placed on farming and the use of land. Dependence, which leads to a decline in biodiversity in the long run. In order to extract energy from cyanobacteria, researchers have invested a significant amount of time and effort over the course of the past few years in an attempt to rewire the photosynthetic machinery of these microorganisms. In addition, for the purpose of extracting the energy that is generated by the bacteria as a result of photosynthesis, the bacteria themselves need to be electrically connected. Electrodes were printed in the form of a highly branched, densely packed columnar structure that was reminiscent of a small city. This structure was created with the help of a three-dimensional printer.

In order for the cyanobacteria to form a community with their neighbors, they required something that they could attach to, and the electrodes have excellent light-handling properties. The electrodes provided the cyanobacteria with everything that they required, which can be compared to a tall apartment building that has a lot of windows. Researchers have found that once the self-assembling cyanobacteria are placed in their new wired homes, they are more efficient than other bioenergy technologies that are currently available. This was discovered after the cyanobacteria Prototype Manufacturing were placed in their new homes.