At the moment, the industries of aerospace, mold manufacturing, and shipbuilding have requirements for the machining accuracy of parts that are getting higher and higher. These requirements are becoming increasingly difficult to meet. However, there are a lot of challenges involved in the process of machining many different parts, especially the complex parts that have space-curved surfaces. Integration along all five axesA computer numerically controlled (CNC) machine tool is one of the essential pieces of equipment that must be purchased in order to achieve high-quality production of difficult-to-machine parts. It has become an essential criterion for evaluating the level of processing performance provided by various pieces of machinery, and one of those criteria is the level of humanization and simplicity with which CNC machine tools can be operated.

Printing in three dimensions (3D printing) is an example of an additive technology, whereas CNC precision machining is an example of a subtractive technology. This is the simplest way to explain the difference between the two. Which of these two choices is the better one?

1. Differences in the components that were used

Materials for 3D printing primarily include liquid resin (used in SLA), powdered nylon (used in SLS), powdered metal (used in SLM), powdered gypsum 3D printed parts (used in full-color printing), powdered sandstone (used in full-color printing), wire (used in DFM), sheet (used in LOM), and many other types of materials. Liquid resins, nylon powders, and metal powders make up the vast majority of the market for industrial 3D printing. Metal powders also make up a significant portion of the market. Plates, or materials that have the shape of plates, are the only acceptable form for the components that go into CNC precision machining. This applies to all of the materials. Once the length, width, height, and loss of each individual part have been calculated, the processing plates of the corresponding sizes are then cut. The manufacturing facility known as Huiwen Zhizao specializes in computer numerical control (CNC) machining and has more than ten years of experience working in this industry. It has everything that is required, including CNC turning, milling, grinding, drilling, and processing equipment. It is also equipped with everything else. If any of our partners have requirements for part processing, we strongly encourage them to get in touch with us so that we can provide a quote for the service.

Plates, or materials that have the shape of plates, are the only acceptable form for the components that go into CNC precision machining. This applies to all of the materials. Once the length, width, height, and loss of each individual part have been calculated, the processing plates of the corresponding sizes are then cut. The manufacturing facility known as Huiwen Zhizao specializes in computer numerical control (CNC) machining and has more than ten years of experience working in this industry. It has everything that is required, including CNC turning, milling, grinding, drilling, and processing equipment. It is also equipped with everything else. If any of our partners have requirements for part processing, we strongly encourage them to get in touch with us so that we can provide a quote for the service.

CNC machining provides access to a wider selection of material options than its 3D printing counterpart does. CNC machining is able to work with common hardware as well as plastic sheets, but the density of molded parts is superior to that of 3D printed parts. Molded parts can be produced using injection molding.

2. Differences in the parts brought on by the molding principles themselves

Since additive manufacturing is a form of 3D printing, the basic concept behind it is to slice the model into a certain number of layers or multi-points, and then to stack the individual layers or bits in the appropriate order, in a manner that is analogous to how one would stack building blocks. Because of this, it is possible for 3D printing to effectively process components with complex structures, such as hollow parts, whereas it is difficult for CNC to process hollow components. These advantages make it possible for CNC products to replace CNC.

CNC milling is the process that is referred to when discussing subtractive manufacturing. After that, the necessary pieces are carved out using a variety of tools, each of which operates at a high rate of speed in accordance with the programmed tool path. As a result, CNC precision machining is only capable of processing rounded corners using a specific radian, while it is unable to process inner right angles directly. Sparking and cutting wire are just two examples of the processes that are required to create inner right angles. Utilizing CNC to perform machining at an outside right angle is not in the least bit difficult. In light of this, components that already have right angles embedded within them might be good candidates for 3D printing. Along with this, there is also the surface. When the component's surface area is on the larger side, it is strongly recommended that you go with the 3D printing option rather than any of the others. It is easy to leave visible lines on the parts that are being machined if the programming and operator experience are not sufficient. CNC surface machining takes a lot of time, and if they are not, it is easy for visible lines to be left behind.

It is not surprising that some individuals hold the misconception that CNC uses cake flour in order to cut a large cake into a number of smaller cakes, whereas 3D printing is thought to use cake flour in order to pile up a cake. This is a very simple idea that doesn't require much thought to understand.

3. Variations in the software that is used to operate the operating system

The vast majority of slicing software that is used for 3D printing can be described as user-friendly and intuitive. Even a user with no prior experience can become proficient with the slicing software with the help of some instruction from an experienced professional and a day or two of practice. The current state of the slicing software makes it very easy to optimize it, and it is now possible to generate supports automatically. Both of these developments contribute to the fact that 3D printing can be popularized among individual users, which is an important step toward the eventual goal of widespread adoption of the technology.

The programming software for the CNC machine is significantly more difficult to work with and can only be operated by properly trained experts. People who come into the world with zero prior knowledge typically need to educate themselves for a period of about half a year. In addition, a CNC operator is essential for the operation of a CNC machine in order for the machine to be used. The acronyms UG, MASTERCAM, and CIMATRON, in addition to the locally produced Jingdiao, are some of the ones 3D printed parts that are used the most frequently. It is still difficult to become proficient in the use of these programs. For many years, Huiwen's primary areas of focus have been the processing of high-precision, high-difficulty, and easily deformed metal and plastic parts, light alloy and composite materials (such as aluminum alloy, carbon fiber, etc.) parts for small and medium-volume production, as well as robot parts procurement and customization services. Due to the complexity of the programming, a component can be processed in a variety of different ways when using CNC. On the other hand, when using 3D printing, the placement position has much less of an effect on the amount of time required for processing and the amount of consumables that are needed because they are more objective.

Due to the complexity of the programming, a component can be processed in a variety of different ways when using CNC. On the other hand, when using 3D printing, the placement position has much less of an effect on the amount of time required for processing and the amount of consumables that are needed because they are more objective.

4. Differences in the way the after-effects are processed

Post-processing options for 3D-printed parts are typically limited and include grinding, oil injection, deburring, dyeing, and other processes that are functionally equivalent to these. Post-processing options for CNC-machined parts include grinding, oil injection, deburring, electroplating, silk screen printing, pad printing, metal oxidation, laser engraving, and sandblasting, amongst others. Other post-processing options include:The following are some of the post-processing options available to you:

In the realm of art, there is a predetermined hierarchy to the ways in which things are discussed, in addition to a variety of subfields that are specialized. The CNC milling process and the 3D printing process are two examples of processes that each come with their own individual advantages and disadvantages. Your choice of the appropriate processing technology will have a significant impact on the outcome of the prototype project you are working on.

Suche

Beliebte Beiträge

-

Vdmx 5 Pc Activation Free Keygen Ultimate

Durch raltavencomp

Vdmx 5 Pc Activation Free Keygen Ultimate

Durch raltavencomp -

Pc UltraISO Premium Utorrent 64 Exe License Full Version [PORTABLE]

Durch rauquigepo

Pc UltraISO Premium Utorrent 64 Exe License Full Version [PORTABLE]

Durch rauquigepo -

lightning Crocs

Durch paulvela

lightning Crocs

Durch paulvela -

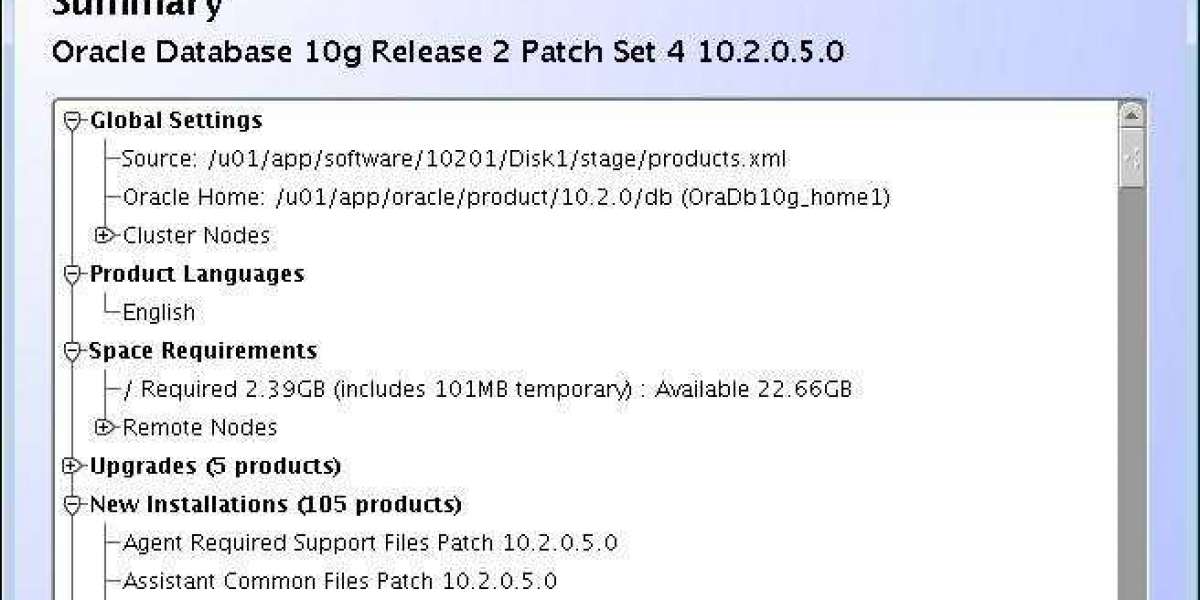

Oracle Database 10g Release 2 10.2.0.5 Utorrent Pc .rar Full Version Activation

Durch hinpodurra

Oracle Database 10g Release 2 10.2.0.5 Utorrent Pc .rar Full Version Activation

Durch hinpodurra -

speedy grade

Durch dianeparker

speedy grade

Durch dianeparker

Kategorien